|

A Guide to Implementing the Theory of

Constraints (TOC) |

|||||

|

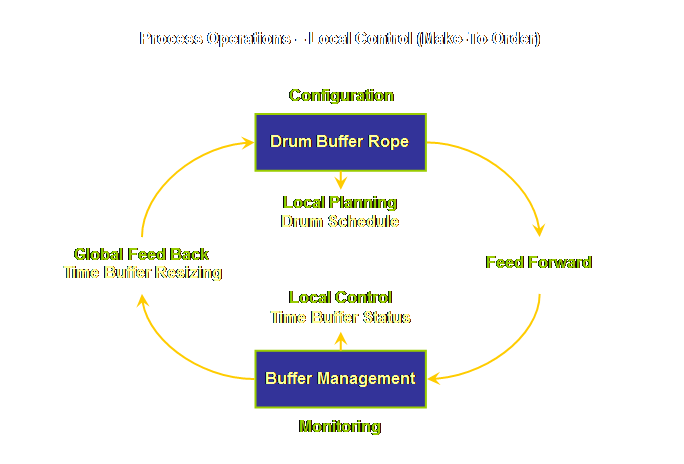

A Motor For Production Drum-buffer-rope is the Theory of Constraints

production application. It is named

after the 3 essential elements of the solution; the drum or constraint or

weakest link, the buffer or material release duration, and the rope or

release timing. The aim of the

solution is to protect the weakest link in the system, and therefore the

system as a whole, against process dependency and variation and thus maximize

the systems’ overall effectiveness.

The outcome is a robust and dependable process that will allow us to

produce more, with less inventory, less rework/defects, and better on-time

delivery – always. Drum-buffer-rope however is really just one part of

a two part act. We need both parts to

make a really good show. If

drum-buffer-rope is the motor for production, then buffer management is the

monitor. Buffer management is the second

part of this two part act. We use

buffer management to guide the way in which we tune the motor for peak

performance. In the older notion of planning and control, the

first part; drum-buffer-rope, is the planning stage of the approach –

essentially the overall agreement on how we operate the system. The second part, buffer management, is the

control system that allows us to keep a running check on the system

effectiveness. However, I want to

reserve the word “planning” and the word “control” for quite specific and

established functions within the solution, functions that we will investigate

further on this page. I want to propose that we step out

a level and instead use the terms “configuration” and “monitoring.” Using this terminology the configuration is

drum-buffer-rope and the monitoring is buffer management. Let’s draw this;

Keep this model in mind as we will return to

it. Now, however, we must return to

our plan of attack and work through the development of the solution. Interested?

Then let’s go. On the measurements page we introduced the concept

of our “rules of engagement” which is to define; the system, the goal, the

necessary conditions, the fundamental measurements, and the role of the

constraints. Then on the process of

change page we introduced the concept of our “plan of attack” – the 5

focusing steps that allow us to define the role of the constraints. Let’s remind ourselves once again of the 5

focusing steps for determining the process of change; (1) Identify the system’s constraints. (2) Decide how to Exploit the system’s constraints. (3) Subordinate everything else

to the above decisions. (4) Elevate the system’s constraints. (5) If in the previous steps a constraint has been broken Go back to step 1, but do not allow inertia to cause a system

constraint. In other words; Don’t

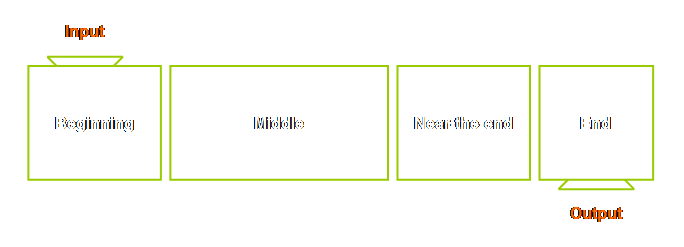

Stop. Let’s also return to our simple system model which

we have so far used in much more general terms and apply it to

drum-buffer-rope. As you will recall

it has 4 sections, or departments or whatever you would like to call them; a

beginning, a middle, a near-the-end, and an end.

In fact we know where the constraint is in our

simple system presented here based upon the discussion in the earlier section

on measurements. It’s located near the

end of the process. This isn’t at all

an unusual place to find a constraint.

Think about it for a moment. If

the constraint was located near the beginning, then all the downstream steps

would always be waiting for work. In

that situation management would most probably go about purchasing further

capacity until they move the constraint further down the process and then

bury it in work-in-process so that it is no longer visible. Let’s draw the constraint in.

Of course we forgot something –

work-in-process. If our model system

is to be anything like our own reality, then it is probably full to the gills

of work-in-process. We had better add

this to our model as well.

So we have completed Step 1 – identify the

constraint. The next step, step two,

is to decide how to exploit the constraint. To make sure that the constraint works as well as

possible on the task of producing or creating throughput for the system we

must ensure that we exploit it fully – essentially we are leveraging the

system against the full capacity of the constraint. This means not only making sure that it is

fully utilized, but also making sure that the utilization is fully

profitable. If you remember back to

the P & Q problem or the airline analogy, is quite possible to have

everything utilized but not make as much profit as is possible. If we increase the output of the

constraint, then the output of the system as a whole will increase also. One of the most effective tactics for

exploiting the constraint, once identified, and improving its output is to

write a detailed schedule for that particular resource and that particular

resource alone – and then to adhere to that schedule. This is the “plan” in this context. Our day-to-day planning “falls out” as a

consequence of the decisions that we make while configuring the

implementation. Let’s add this to our

model.

If we continue to operate in this fashion we can

reduce work-in-process considerably.

Let’s show this before introducing some further drum-buffer-rope

concepts.

Sometimes using the word “protect” makes it easier

to understand this step than using the correct term which is

“subordinate.” In fact, we subordinate

the non-constraint resources in order to protect the constraint and

the system as a whole. Let’s examine

this is a little more detail. In the process of change page we described

subordination as avoiding deviation from our plan, and the plan in this case

is our constraint exploitation schedule in the previous step. We described deviation from plan as (2); (1) Not doing what is supposed to

be done. (2) Doing

what is not supposed to be done. We can therefore describe subordination as; (1) Doing

what is supposed to be done. (2) Not doing what is not supposed

to be done. By doing what is supposed to be done in accordance

with our plan we protect the constraint and the systems as a whole. Moreover, by not doing what is not supposed

to be done in accordance with our plan we also protect the constraint and the

system as a whole. Let’s examine this

with our simple model. As we use up our supply of excess work-in-process,

it is likely that the constraints will begin to “starve” from time to

time. Work will not arrive in

sufficient time for it to enter the constraint on schedule. We need to replace our local safety everywhere

(our excess work-in-process) with some global safety right where it is

needed, in front of the constraint. We

need to buffer the constraint. We need to do what is

supposed to be done in order to protect

the constraint from shortages. In fact we would normally have made our buffering

decisions before we even began and therefore reduced our work-in-process and

lead time in line with these pre-determined targets. Let’s assume for a moment then that the lead time

allowed for work to travel from the start of the process to the start of the

constraint was 18 days prior to the implementation. Well, in fact, it could be 18 hours for

electronics or the paper work in an insurance claim, or it might be 18 weeks

for heavy engineering. But let’s use

days in this example. The rule of

thumb to apply is to halve the existing lead time (3). Therefore the new lead time becomes 9

days. If halving the lead time sounds

horrendously short, it is not. Most of

the time the current work-in-process is sitting in queues doing nothing. You can easily check this for yourself –

got out and tag some work with a flag or a balloon or a bright color and then

watch it. It will sit. This 9 day period becomes our buffer

length. To this 9 day buffer we apply a second rule of thumb

and divide the buffer into zones of one third each (4). We expect most work to be completed in the

first 2 thirds and be waiting in front of the constraint for the last third

of the buffer time. Thus we expect our

work to take about 6 days of processing (and waiting-in-process) and 3 days

of sitting in front of the drum. If 3 days sitting in front of the constraint sounds

terrible, then remember that prior to

the implementation, the system allowed work to sit for at least another 9

days. Nine plus 3 is 12 days

sitting. Which would you rather have

12 days or 3 days? More importantly,

which would your customer prefer? We now can protect our system constraint by ensuring

that there is always work for it to do.

Thus we ensure its effective exploitation – and with much less total

material or lead time than before. Let’s add the buffer to our diagram.

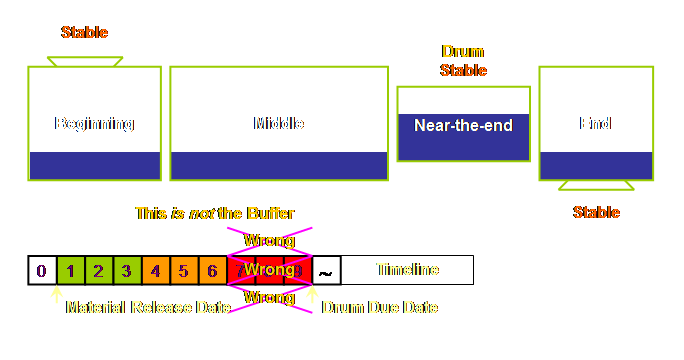

Please be careful, on the diagram above we have

drawn units of time – the zones and the buffer – as space on our

diagram. Don’t let this confuse

you. The zones equate to time allocated

in the plant to protecting an operation whose position and function is

critical to the timeliness and output of the whole process. The zones do not equate to the position of

work in the plant. In fact we will

return to this shortly and try and draw the diagram more realistically to

represent time. Why is this whole period from material release to

the constraint considered as the buffer?

Schragenheim and Dettmer consider that this is one of two unique

aspects of buffering in Theory of Constraints. “The reason buffers are defined as the

whole lead time and not just the safety portion is that in most manufacturing

environments there is a huge difference between the sum of the net processing

times and the total lead time. When we

review the net processing time of most products, we find it takes between

several minutes and an hour per unit.

But the lead time may be several weeks, and even in the best

environments several days.

Consequently, each unit of product waits for attention somewhere on

the shop floor for a much longer time than it actually takes to work on

it.” “So it makes sense not to isolate

the net processing time, but to treat the whole lead time as a buffer – the

time the shop floor needs to handle all the orders it must process (6).” The other unique point is that buffers are, as we

have mentioned, measured in time.

Firms in non-drum-buffer-rope settings consider a buffer to be a

measure of physical stock; 6 jobs, or 6 orders, or 10 batches, or 4000

pieces, or whatever. In

drum-buffer-rope a constraint buffer is a measure of time; hours or days of

work at the constraint rate located between the gating operation (material

release) and the constraint. In fact,

there are two ways to look at a buffer, either from the perspective of a

single job, or from the perspective of the system as a whole. Let’s consider this for a moment. Let’s assume for the sake of simplicity that all of

our jobs are of equal length. Let’s

assume then that each one takes 1 day of constraint time. In this case each job has a 9 day buffer to

the constraint. That is, it is

released 9 days prior to its scheduled date on the constraint. This is the perspective of a single

job. The constraint, looking back,

will see 9 one-day jobs at various stages in the process; this is the

perspective of the system as a whole. What then, all else being equal, if all of our jobs

now take half a day on the constraint?

Each job sees a 9 day buffer, the constraint looking back will see 18

half-day jobs at various stages in the process, but the aggregate load is still

9 days, this is the perspective of the system as a whole. Let’s do this one more time. Each job now takes quarter of a day on the

constraint. Each job still sees a 9

day buffer, the constraint looking back will see 36 quarter-day jobs at

various stages in the process, but the aggregate load is still 9 days from

the perspective of the system as a whole.

It is time that is the measure of the buffer. Let’s labor this point for a moment because it is so

important. Measuring a constraint

buffer in units of time is unique to drum-buffer-rope because acknowledgement

of the existence of a singular constraint within a process is unique to

drum-buffer-rope. We can apply this to

both the constraint buffer size and the constraint buffer activity. Let’s look at constraint buffer activity first. By considering only one station, or step, or

procedure, we need only to know one set of average times for that place or

action for all of the different types of material units that pass through

it. We could look at this as follows; At a manufacturing constraint an hour is

an hour but the number of units may differ The number of physical units may differ because

different types of material using the same constraint may use different

amounts of constraint time. In fact,

even the same type of material will display some variability unless the

constraint is a totally automated procedure – but these will largely average

out. How about constraint buffer size then? The unique perspective brought about by the

designation of a singular constraint allows us to define the length of the

buffer in time also. Essentially the

buffer is sized and “sees” the duration from the gating operation to the

constraint due date. Moreover the

buffer “sees” committed demand – work that has already been released

to the system. Constraint buffers,

divergent/convergent control point buffers, assembly buffers, and shipping

buffers are all of the same basic nature. Maybe it is much simpler to say that; We protect time (due date) with a time buffer There is, however, one other buffer type that we are

likely to come across in manufacturing – a stock buffer. There are two places that these occur at in

manufacturing; they are at raw material/inwards goods in all process

environments and at finished goods in a make-to-stock environment. These are actually supply chain buffers;

they represent the two places that the supply chain must interact with processing

– before the beginning of the process and after the completion of the

process. We need to ensure that we

always have an adequate supply of raw material prior to the process to meet

consumption and we need to ensure that we always have an adequate supply of

finished goods post-production to meet demand. We will examine these types of buffers

later on this page. They are also

examined in more detail on the supply chain pages – especially the

replenishment page. However, let’s

confine ourselves at the moment to constraint buffers. We need to labor the issue that the

constraint buffer is a measure of time.

Let’s do that. Many, many, people say that they do understand the definition of a drum buffer or of a

constraint buffer when the evidence is that they do not. Too often our prior experience causes us to

think of buffers in terms of physical stock, and too often we consider zone 1

as “the buffer.” Let’s see.

In part, this is due to our prior manufacturing

experience with MRP II systems and push production which tends to blind-side

our interpretation (see the sections on Buffer The Constraint and Local

Safety Argument in the next page – Implementation Details – for further development

of this aspect.) In part, the problem

also lies in the way we try to draw time as space on our simple diagrammatic

representations. The only way to draw

time is to draw a sequence of diagrams.

Let’s do that. We will follow a slice of work – ones day’s worth –

through the process to the drum. We

will use our 9 day buffer as we derived above, so this slice of work is the

drum’s work for one day 10 days out from the scheduled processing date. There are 5 products (units, jobs, batches,

whatever) in our slice. The products

are “lilac,” “red,” “green,” blue,” and “orange.” The time interval, for the sake of clarity

in this example, is course – days – rather than finer divisions of hours or

less that we might expect to find in reality. Imagine that within the departments (“beginning” and

“middle”) of our generic process we have the tools of our particular trade;

be they desks in a paper trail, admission or beds or clinical units in a

hospital, or work centers in a manufacturing system. The 5 products could be at any time waiting

or moving between jobs or being worked upon.

The resolution of this detail isn’t important to us here. Probably in the day before the release date the

planner knows what will be released.

The planner might even have the orders “cut” and waiting but

unreleased (and hopefully unknown to the floor – to avoid people working

ahead of time). Let’s draw this.

We have also drawn a timeline in. It is colored according the buffer

zones. Zone 3 is the “green zone,”

zone 2 is the “orange or yellow zone,” and zone 1 is the “red zone.” On the first day of the schedule all the products

are released (as scheduled) and are in zone 3 of our time buffer. Their physical location at the end of the

day is as follows.

After another day we are at day 2 and still within

buffer zone 3 the process looks like this.

By day 4, one day into buffer zone 2 we see the work

has evolved as follows.

The next day, day 5 (buffer zone 2), the work looks

like this.

At the end of day 6 – the last day of buffer zone 2

we see the following.

Let’s go out to the end of day 7 and see what

happens.

Let’s now look at the situation at day 8.

So, let’s reiterate once more; buffer zones equate

to the time allocated in the plant to protecting operations whose position

and function are critical to the timeliness and output of the whole process, buffer

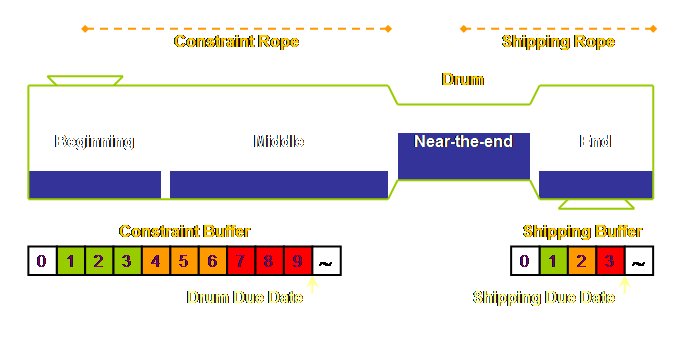

zones do not represent the physical location of work in the plant. We know how to protect the constraint, now let’s see

how to protect everything else. So, we know now how to protect the constraint using

a buffer, we therefore know how to do the first part of subordination – doing

what we are supposed to do in order to protect the constraint. Now we need to examine the second part of

subordination – not doing what we are not supposed to do. First, let’s repeat the diagram that we first drew

prior to our journey along the buffer.

In order to maintain stability in this system, the

rate at which the gating operation allows the admission of new work to the

system must be the same as the rate of consumption at the drum. What would happen then if our constraint

breaks down for a short period? It has

no spare capacity, so we can’t speed it up (allow it to work longer) to catch

up to the work again. If we were to

continue to admit work as though nothing had happened then work-in-process

would increase a little. Probably not

enough to notice, but over a couple of different instances it would begin to

build up. Thus we need to make sure

that we admit new work into the system at the same rate as the constraint is

consuming it. The constraint as we

know is the “drum” of our system, beating out the rate at which the whole

system works, including the gating operation.

The rate is communicated to the gating, or first, operation by the

“rope.” We need to add this to our

diagram. If you like, the schedule of the gating operation is

the schedule of the drum off-set by a rope length of time. The rope length is the same as the buffer

duration; the gating rate is the same as the drum rate. “Tying” the rope between the drum and the

gating operation ensures that excess work can not be admitted, or that normal

work can not be admitted too soon. This

is part of not doing what is not supposed to be done

in order to protect the system from excess

work-in-process. Excess work in

process results in longer than necessary lead times and poorer quality. Ultimately excess work-in-process also

impacts upon the throughput of the constraint. Another way of looking at the rope is to consider it

as a real time feedback loop between the drum and the gating operation. Although the constraint can not recover from

down-time, hence the need to exploit and protect it, the non-constraints can

recover from down-time. Generally the

non-constraint parts of our system don’t work at the same rate as the whole

system – at least over short periods of time.

The non-constraints have sprint capacity. They can and do process more work when

necessary to catch-up after a “bump” in the system by operating at normal

rates for longer periods. They can

also process less work when not needed by operating at normal rates for

shorter periods. We might consider the increased duration of

non-constraint processing (in order to catch up) as the “doing what is

necessary” part of subordination, and the reduced duration of non-constraint

processing (to avoid over-production) as the “not doing what is not

necessary” part of subordination. It

is critically important that we do this. In the Toyota production system, kanban perform both

of these functions. In

drum-buffer-rope this is performed by the “roadrunner” concept. When we have work to do, we do it. When we don’t have work to do, we don’t do

it. We saw this in the form of the

traffic light analogy earlier in the page for process of change. Non-constraints should never “slow down,”

they should either be fully-on or fully-off (maybe that should be normally-on

or normally-off). Either creating

throughput or protecting throughput.

We will revisit this theme on the next page; implementation details. We have seen how we now have 9 days of work in

process in our example – down from the initial 18 days. There are 6 days of work in process in

zones 3 and 2 and three days in zone 1.

But we can think about it in another way. By halving the work-in-process we have

removed 3/6ths of the work from the system.

We have another 1/6th sitting in front of the constraint, so in effect

we have just 2/6ths or 1/3rd of our previous work-in-process actually on the

floor being actively worked on or sitting in queues. Imagine your process at it stands today but

with just 1/3rd of the work actively being worked on by the non-constraints

or waiting-in-process; wouldn’t things really begin to flow in that

situation? Nevertheless, in order for that material to flow, it

is critically important to protect sprint capacity by proper

subordination. Sprint capacity

interacts with overall buffer size and hence manufacturing lead time. We will investigate sprint capacity more in

the next section. Protecting sprint

capacity means that we never admit work into the process just to keep people

busy – never. Of course you will have noticed that we have so far

used the departmentalized version of our system model. To some extent this was intentional because

when you first approach a drum-buffer-rope implementation, the process will

be departmentalized. However, what we

would like to see after a short while is a better appreciation of the system

as a whole. Conceptually it should look more like this;

For the shipping buffer, we again apply the same

rules of thumb as we used for the constraint buffer. Let’s assume, for the sake of the ease of

the mathematics, that the process downstream from the constraint to shipping

currently takes 6 days. We halve that

to give us a new lead time of 3 days.

And then we divide that into buffer zones of thirds and expect almost

all work to be completed after 2 days and either waiting for shipment or

already shipped 1 day prior to the shipping date. This is what we arrive at;

Thus our original 24 day process becomes a quoted

delivery time of 12 days. The system

should be able to produce more because we will have made every effort to

exploit the constraint, and the non-constraints only work on material that is

required to support the constraint schedule. So, to summarize, subordination is the instruction

to the non-constraints. It has two

main components. Firstly; in order to protect the system as a whole

we must not starve the constraint – we must not underload

the system. This will ensure maximal

output as per the exploitation strategy of the constraint. Of course we could make the buffer quite

large and never have to worry about starving the constraint, but that is

where most systems are today (and they still starve the constraint). So we need to do something else as

well. Secondly; in order to protect

the system as a whole we must not flood the non-constraints – we must not overload the system. This will ensure adequate sprint capacity

to ensure maximal output as per the exploitation strategy of the constraint

and high due date performance. It will

also ensure a much reduced lead time. Thus we have covered all three aspects; the drum,

the buffer, and the rope. We have also

covered the first three steps of the 5 focusing steps; identify, exploit, and

subordinate. If we have fully exploited the leverage point, and

subordinated everything else, then the next thing to do is to elevate the

constraint. But first, let’s examine

an alternative initial buffer sizing rule. So far we determined our initial buffer sizes by

taking 50% of the existing lead time over the part of the system that we

wished to protect. There is another

lesser-known rule that we can also use.

We can take 3 times the back-to-back time for a job to transverse that

part of the system that we wish to protect. From time to time jobs are expedited for a number of

reasons, therefore people will know from direct experience, or will have good

intuition, for the back-to-back time and from that a buffer duration can be

obtained. Elevation may require that some additional

investment be made to purchase additional capacity that will produce

additional throughput, preferably at more than pro-rata. Remember we are trying to decouple

throughput from operating expense thereby driving productivity and

profitability up;

If at any time a constraint is broken then we must

look for the next constraint. In fact

we should know from buffer management where it will be before we even get

there. However, many times an initial

physical constraint is broken and a policy issue takes its place. Goldratt’s admonishment not to let inertia

become a system constraint is a plea to look at which policies block us from

moving forward even further. Really

this is a plea to Don’t Stop! There are a few traps for those of us who are new

players. Some of the definitions have

changed over time. In this case to be

forewarned is to be forearmed, let’s do that.

Here we have used the term “drum” to describe the entity that

determines the rate at which the whole system works – be that an internal

constraint, or as we will see, an external market demand. However the term “drum” is also used to

describe the drum schedule, in fact some insist that the drum is the schedule.

Clearly when the constraint is in the market this definition makes

more sense. Both are in use, some

would argue that these different definitions are simply different manifestations

of the same concept. If we accept

this, then that ought to keep everyone happy. Likewise, the “rope” has been used here to describe

the off-set between the drum and the gating process; however, it too is

subject to a more restrictive definition of the “gating schedule.” Once again these are different

manifestations of the same concept.

They are not mission critical. We have so far examined the development of the

drum-buffer-rope solution – our motor for production – and we have done that

within the framework of our 5 step focusing process. We also presented a model for the

configuration and monitoring of this solution, to this we have added a local

planning aspect; our schedule for the exploitation of the drum. Let’s repeat the model here and note that

we are looking at the specific case of make-to-order.

(1) Local

Control; the day-to-day exception reporting that indicates when there may be

a potential due date violation. (2) Global

Feedback; longer term trend-reporting that suggests a particular buffer needs

to be resized to be fully effective. Buffer management is crucial; it filters important

signals from the day-to-day noise of the system thereby alerting us to

potential problems before they become real problems and it provides a

self-diagnosis that neither too much and nor too little protection is made

available for each case. The self-diagnosis

feeds back into our configuration and guides improvements in the overall

dynamics of the implementation. Let’s modify our model to incorporate this.

“A reactive mechanism

that handles uncertainty by monitoring information that indicates a

threatening situation and taking appropriate corrective action before the

threat is realized.” The subdivision of buffer management into local

control and global feedback will, I hope, make it easier to understand this

important concept. Let’s now investigate the various stages of local

control and then global feedback in a make-to-order environment. We release work a rope length ahead of the due date

at the point that the buffer protects.

In most cases that is more than sufficient to insure that the work

arrives in good time. But as we know

sometimes stuff happens. We need some

local control to ensure that when stuff does happen we know the correct

priority to return the system to one of stability. We need to know the status of the current

make-to-order work orders that are already released to the system to be

worked upon. Schragenheim defines the buffer status as follows

(8); Buffer Status = (Buffer Duration – Remaining

Duration) / Buffer Duration The buffer status is synonymous with buffer

consumption. Let’s look at an example. Here we have the buffer status for 6 jobs

due in the next 5 days.

Of the current jobs; job 6 with a buffer status of

44% is no problem, we should leave it alone.

However jobs 2 & 4 both have a buffer status of 66% or more. They have both begun to penetrate zone 1 of

the buffer, the red zone. Of the two,

which is the greater priority? Clearly

it is job 2; this is the one with the greater buffer status value and is the

one that we should first concentrate our attention on. Thus the buffer status drives the work order status

once the job has been released to the system.

We therefore have local control by exception in order to meet our

global objectives. Buffer status is

viewed from the perspective of a single job. What then, where we have short ropes and long ropes,

surely that is more complicated? Again

the buffer status allows the direct comparison of work orders that have

differing buffer lengths within the same process. Let’s have a look.

Don’t confuse short jobs and long jobs with “rush”

and “standard” orders. That particular

prioritization takes place in the order queue and not in the manufacturing

lead time. In a make-to-order system where there is a

commitment to meet a due date, then; Current Work Order Status = Buffer Status It may seem redundant to state this, however, it

will become clearer when we deal with make-to-stock. In a make-to-stock environment the stock

order status can vary over time due to the natural variability of the process

itself and due to changing market demand as well. This additional factor is absent from the

make-to-order environment, here we have a commitment and we must meet that

commitment. Ever been in the situation where you have a nice

workable schedule – all the critical areas have been satisfied (all the

“squeaky wheels” are oiled), and then someone announces “you know the

material that they said would be on the truck this morning, well its not!” What are you

going to do? This job is down for the

gating operation this morning, you don’t have it, and it’s the Friday before

a long weekend. Sound improbable? Not at all. Officially you can wait. You can wait until up to 50% of the buffer

to the next stage has been consumed.

Until then the work can still be released, after that it must be

rescheduled. In fact the same logic can be applied when

back-scheduling from the shipping date.

Sometimes commitment to different customers and/or varying rope

lengths will result in a conflict where more than one job simultaneously

requires the constrained resource. One

solution is to start some work on the constraint even earlier than

required. If a conflict still exists

then some work may have to start later than we would like, in effect the late

start pushes that job out so that it begins to consume part of its shipping

buffer. Again, so long as not more

than 50% of the shipping buffer is consumed then the job can proceed,

otherwise the commitment to the client must be renegotiated – the due date

must be pushed out further (9). Stepping back one step further, the same logic

applies in-turn when back-scheduling from the drum date to material release,

now for a different reason than material lateness; we can apply the same

rules as before. In fact, this is

really local planning rather than local control, but it is easier to

understand now rather than earlier. We want to insulate our customers from the

variability and dependency within our system.

We can do this in two ways; (a) proper subordination so that

non-constraints have adequate sprint capacity, and (b) buffering so that even

when sprint capacity is exhausted for what ever reason (stuff sometimes

happens) we still have some safety time up our sleeves. Of course, we have “rolled-up” our local

safety everywhere into a few discrete and critical places where it will be of

maximal benefit. Work order status – our buffer status – tells us in

real time when to facilitate an order, and in what priority we should do so

if more than one work order requires facilitation at the same time. It is local, immediate, and

pre-emptive. A buffer status that

exceeds 66% has consumed more than 2/3rds of its buffer capacity, colloquially

we say that it has penetrated the red zone. Until the order is complete and at the buffer origin

we don’t know to what “depth” the red zone has been penetrated. However, once the order is complete and the

degree of penetration is known we can call this degree of penetration a

“buffer hole.” Let’s draw this.

What then is an acceptable frequency for buffer hole

occurrence? Well that depends. In a relative sense buffer holes should

neither be too frequent nor should they be too rare (8). A more concrete suggestion is something

less than 10% (11). Clearly the zone 1

buffer hole operates in only a limited number of cases. It is a fine example of exception

reporting. After all we want a robust

system, not one that must be pampered every hour of the day. If we take our example of a 9 day constraint buffer

we would expect most jobs to be completed before 6 days and to be waiting at

the constraint 3 days prior to their scheduled operating date. Of the remaining few we must go and look

for them in the prior operations to ensure that they will reach the constraint

before their scheduled operating date there.

If we then look at aggregate data for, let’s say 25 jobs with roughly

a 5% level of buffer hole occurrence, then that data might look something

like this;

Buffer holes are viewed from the perspective of the

system as a whole. From the buffer hole data we can construct a more

meaningful measure. In the

measurements section we discussed two local performance measures; unit days

late and unit days wait. In a

for-profit environment these are known as throughput-dollar-days (late) and

inventory-dollar-days (wait). I prefer

to add “late” and “wait” to these measures because to those who are

unfamiliar with the terms it is hard to know what they mean or their

significance. And these two measures

are so important to the overall success of drum-buffer-rope that we can’t

afford to lose people through obscure terminology.

Now let’s consider the other side of the equation –

inventory. Have you ever had material

go to the outsourcers that seemed to have a life of its own – I mean it

didn’t seem to want to come back. “I

know we said this week, but one of the guys is off and now it will be next

week”. Even small jobs at the

outsourcer can have major implications if it stops an otherwise completed job

from being shipped. Of course we will

pick that up in our buffer holes and in terms of the measure of

throughput-dollar-days late. However,

sometimes, the response is to add some additional just-in-case work to guard

against this in the future. Sometimes

people will also admit new work in order to keep a particular center

“busy.” Sometimes the post-constraint

areas aren’t always diligent about keeping work moving. We can guard against these types of incidences

with our other local measure inventory-dollar-days

wait. Adding or building

work that may still be on-time is effectively captured with this

measure. Moreover it can be applied to

sub-sections of the whole process. It

helps to stop the squirrels in the business from storing inventory

just-in-case. Throughput-dollar-days late and

inventory-dollar-days wait are the two measures that effectively allow us to

monitor the stability of the system, they are local measures with

implications for global feedback. Just

two measures. You couldn’t wish for

better could you? OK, one measure,

some people can’t be pleased, but we will have to suffer two. If buffer holes begin to occur in the red zone

significantly more frequently, or indeed less frequently, than our target

level, we must do one of two things; (1) adjust the buffer or (2) adjust the

sprint capacity. Of the two, adjusting

the buffer is the most rapid and easy to do.

We simply change a policy on buffer size and accept a small

increase/decrease in total work-in-process and manufacturing lead time. We can also use the equivalent unit-day

late measure to monitor this need. If a buffer hole trend begins to “emerge” but is not

yet too troublesome, then it may indicate the erosion of sprint capacity in

the system and the area of that erosion, or it may indicate some special

cause – a machine or quality or operating problem. The cause should be tracked down,

monitored, and rectified if possible.

There are definitely cases where buffer holes arise from some

innocuous change in the process, “we used a different glue because it was

cheaper,” which has a downstream impact that was not anticipated, “yes but we

are spending more time on removing glue marks.” Emergent buffer holes also indicate

potential future constraint points. We

will investigate these factors in more detail in the page on implementation

details. Buffer management is the monitoring aspect of our

implementation and monitoring model.

It provides both local control and maybe more importantly a global

level feedback into our drum-buffer-rope basic configuration. We only “tune” the basic parameters when

the system behavior tells us that we need to do so. We only do what we should do, and we don’t

do what we shouldn’t do. If we continue to apply our plan of attack, our 5

focusing steps, then it is unavoidable that at some stage we will elevate our

system constraint so that it moves to the market. What are we going to do then? Let’s see. If the bottleneck to the system is the market, then

we must treat the market as the constraint and subordinate the process

constraint (now best called a control point) to the market. This means only making things that the

market needs and not making the things that the market doesn’t need

(overproduction). Essentially the drum

is now in the market place, but we can visualize this by placing the drum at

dispatch – the customers’ desired due date.

You see, the control point, our internal weakest

link, isn’t really so critical anymore, in fact in the next section we will

see how to operate without explicit scheduling of the control point at

all. While the internal weakest link

is no longer critical, it is still however central to our operation. It becomes our leverage point. It is certainly seductive to consider that our

leverage point should be where we have placed the drum; that is at the

customers required due date. This is,

after all, the point where the internal system and the external market

interact. This certainly appears to be

the place where we can maximize leverage.

We can easily test this in a negative sense by running a few orders

overdue. We know what the reaction of

the market will be. It might be better

to consider this interface between the internal system and the external

market as a transfer point. We will

look at transfer points again in the introduction to the supply chain pages. If we step back in our logic we will find that the

characteristics of our due date performance is still determined by our

internal weakest link. The greater the

difference between the additional capacity of the internal weakest link and

the market demand; that is the amount that internal capacity exceeds external

demand, the smaller the buffer and the shorter the manufacturing lead time. Conversely, the lesser the difference the

greater the buffer and the longer the manufacturing lead time. It is the characteristic of the timeliness

of the system that is important; this is an aspect that we will explore in

further detail later on in the paradigms page. For now let’s be certain that it is the

interaction of the internal weakest link within the overall system that

determines this characteristic. This is where we leverage

the whole system from. Once the constraint is in the market then we should

do our utmost to continuously increase the market demand while increasing

internal capability at the same time – so as to keep the constraint within

the market and to be able to provide that market with a very high level of

service. In fact our service level must

be much better than anyone else – and it will be! In a market constrained environment we can continue

to use drum-buffer-rope with a market drum and an internally scheduled

control point, referred to as traditional drum-buffer-rope, or we can begin

to use a more recent development called simplified drum-buffer-rope or S-DBR

(12). Simplified drum-buffer-rope is

at the heart of the Theory of Constraints make-to-stock solution – and that

is where we are heading next – so let’s investigate simplified drum-buffer-rope

first in our more familiar make-to-order environment. Simplified drum-buffer-rope is an excellent reminder

to heed the 5th step of the 5 focusing steps; don’t

allow inertia to become a system constraint. When most drum-buffer-rope implementations

move the constraint into the market, they continue to protect the internal

process, at very the least, at 2 places, the internal weakest link or control

point, and the shipping date. Do we

still need to do this? The answer

appears to be no when the internal weakest

link is working at 80% or less of its capacity to supply the market

demand. In this situation it is quite

safe to roll the safety up into one global safety buffer instead of two or

more. How do we schedule such a system? Well, instead of having a constraint schedule and a

shipping schedule we now have only a shipping schedule with a gating process

off-set by a full shipping rope length.

The schedule is still loaded against the capacity of the internal

constraint – available hours per day, or available hours per week, over the

average manufacturing lead time, but the only detailed schedule is for

shipping. More correctly the schedule

is loaded against up to 80% of the aggregate capacity of the internal control

point. A queue of some duration will

still naturally build and maintain itself in front of the weakest link, but

it is no longer scheduled. Let’s try and draw this.

Avoiding the need to determine a detailed schedule

for the internal constraint/control point is especially useful in situations

where capacity is made of up multiple similar machines – some permanently

set-up for certain ranges of jobs, some for large batches, some for small

batches, and so forth. Another case

might be special dependencies or set-ups.

In this situation the foremen and their people will know better than

any planner how best to exploit the system.

Leave them to it, they know what to do. There is one further alteration to

the basic drum-buffer-rope concepts that we must address and that is the

buffer itself. Simplified

drum-buffer-rope was initially described with a two-zone buffer; comprising a

green zone and a red zone. However the

authors, being pragmatists, have since revised this to the basic 3 zone

buffer as we have used throughout here.

So, let’s redraw the system with a 3 zone buffer.

Simplified drum-buffer-rope, although developed as a

consequence of make-to-order systems moving towards the desired position of

being market constrained, is an ideal system for operating a make-to-stock

operation. In the following sections

we will look at, firstly, a transitional system that uses full “traditional”

drum-buffer-rope for make-to-stock and then, secondly, develop the argument

for using simplified drum-buffer-rope – first in make-to-stock and then in

make-to-replenish. Right now, however,

we must introduce the concept of stock buffers. There are two places where the supply chain

interacts with manufacturing – at the beginning of the process and at completion. It isn’t much good to have excellent

on-time service for make-to-order if we don’t have the necessary raw

materials on hand to begin with, nor is it very useful in make-to-stock if we

don’t have sufficient resultant stock-on-hand at all times. Often we don’t even think of raw materials

(or inwards goods) and finished goods as a part of the supply chain, they

seem, and in fact they are, integral to the manufacturing process. But by their very nature they are the end

of one supply chain, and the beginning of another. In supply chain each and every node for each and

every stock becomes its own buffer.

Each node must contain sufficient stock to meet demand (and variation

in demand) during the period from the beginning of one re-order/resupply

cycle to the next. In both

make-to-order and make-to-stock environments a stock buffer for raw material

input occurs at the beginning of the process.

In manufacturing make-to-stock environments a stock buffer for

finished goods output also occurs at completion. Let’s add these stock buffers to our

diagram.

To understand why we buffer these stock positions

just prior to, and just after, manufacturing in units of material rather than

units of time we need to consider how we determine both the stock buffer

activity and the stock buffer size. Let’s examine stock buffer activity first. Why do we use units of material for stock buffer

activity when we use units of time for the constraint, control points, and

shipping buffer activity? The reason

is that now the number of units is invariable but the amount of time or

demand that they “cover” is variable.

Sometimes demand is high and we utilize the same number of units

faster and over a shorter period.

Sometimes demand is low and we utilize the same number of units more

slowly and over a longer period. But a

unit is still a unit. Thus; At a stock node a unit is a unit but the

hours may differ The selection of units of time or units of material

isn’t arbitrary; it is based on the nature of the step we wish to

protect. If time is invariant (an hour

is an hour) then we use time. If

quantity is invariant (a unit is a unit) then we use quantity. Maybe it is much simpler to say that; We protect stock with a stock buffer What about the stock buffer size then? The unique perspective brought about by the

designation of a stock node allows us to define the length of the stock

buffer in time. Essentially the buffer

is sized and “sees” a duration that extends through one period of the

re-order/resupply cycle. However, the

buffer now “sees” uncommitted demand – we can not tell how much we

will sell in the next hour or the next day or whenever. Therefore, we must once again substitute

“non-variable” units of stock in place of the variable amount of time or

demand that they “cover.” Thus the

replenishment buffer size is also measured in units of quantity. We will return to the part the

re-order/resupply time plays in determining the stock buffer size soon. In many make-to-stock systems it might be inelegant

but never-the-less quite effective to give make-to-stock orders a due date

for completion as we would in make-to-order jobs and to therefore operate a

shipping buffer. The shipping buffer

then supplies a stock buffer. The

stock buffer itself will also contain some measure of safety. This undoubtedly overdoes the safety

aspect, as we have system safety in safety stocks and we have system safety

in the shipping buffer. However, so

long as this is recognized, and so long as it works, then it shouldn’t be a

problem. Let’s have a look at such a re-order system using full drum-buffer-rope.

In traditional reorder approaches to make-to-stock

using min/max systems we can “wing” a reorder system using recent rates of

consumption to give us a “time remaining until order release.” Orders with the least time remaining get

priority. Priority = [(Stock-On-Hand + Work-In-Process –

Orders) – Reorder Point] / Consumption Such an arrangement of course also allows for a very

effective mixed make-to-order/make-to-stock operation. Probably the greatest majority of

businesses currently operate in this manner.

This transitional example is shown with an internal

constraint. In this case we can try

and supply all of the demand but it is not possible. Therefore, either we must accept that some

of the stock buffers will be out-of-stock some of the time, or we must reduce

the total number of stock items – just as we must turn down some orders in an

internally constrained make-to-order system.

Despite the protests of purists, make-to-stock systems often start

from this position but it isn’t so easy to recognize. In an internally constrained make-to-order system

the turning down of orders is often active; we make a decision to do

so. In an internally constrained

make-to-stock system the decision is sometimes passive; the customer

makes it for us. Moreover the customer

may never “voice” disappointment at a stock-out, they may simply go elsewhere

and we might not ever know. Really, we want our initial internally constrained

make-to-stock operation to move towards being market constrained. Think about it. We need sufficient stock so that our customers

can always find what the want, and when they want. Such market constrained systems tend to be

replenishment systems which we will discuss in a moment. The objective of this transitional and

traditional drum-buffer-rope stage is to make available the needed capacity

to get to the required level of output.

The identification, exploitation, and subordination steps of full

drum-buffer-rope will uncover existing capacity that was previously

unrecognized. We need to understand why this transitional stage is

so common. One reason without doubt is

that materials requirements planning (mrp) and material resource planning

(MRP II) use time as the default for treating stock orders. This is so common that we don’t even

challenge the assumptions behind it.

To do so however, we need to introduce a new concept. We need to introduce the concept of replenishment

stock buffers. As we move from being internally process

constrained, to being externally market constrained – a normal consequence of

implementing drum-buffer-rope – then there is an opportunity to move from

fixed-quantity variable-frequency make-to-stock to something superior. We will call this superior mode of

operation make-to-replenish – as distinct from make-to-stock. First, however, we need to be aware of a

subtlety. We need to remind ourselves

of our plan of attack, our 5 focusing steps.

They are; (1) Identify the system’s constraints. (2) Decide how to Exploit the system’s constraints. (3) Subordinate everything else

to the above decisions. (4) Elevate the system’s constraints. (5) If in the previous steps a constraint has been broken Go back to step 1, but do not allow inertia to cause a

system constraint. In other words; Don’t

Stop. We know that the constraint is in the market, so

where then is our leverage point?

Using the terminology of Dettmer (13) it has to be somewhere within

our span of control rather than our sphere of influence. Just as the due date was a seductive place

to consider leveraging from in make-to-order, so too here is the finished

goods stock. After all, we must have

the right material in the right place at the right time –

always. However, just as with due dates in make-to-order,

the greater the difference between the additional capacity of the internal

weakest link and the market demand; that is the amount that internal capacity

exceeds external demand, the smaller the queue in front of the weakest link

and the shorter the manufacturing lead time and thus the smaller the stock

buffer that is required. Conversely,

the lesser the difference the greater the queue in front of the weakest link,

the longer the manufacturing lead time, and thus the greater the stock buffer

that is required. Again, it is the

characteristic of the timeliness of the system that is important and it is

the interaction of the internal weakest link with the overall system that

determines this characteristic. It is

from the internal weakest link that we leverage the whole system. Does that seem logical? Then let’s move on. In a make-to-replenish environment, stock provides

the system safety against both the variation in demand from the customer and

variation in the time to needed to re-order and resupply the stock. Therefore we don’t need to use a shipping

buffer; the stock is our buffer. This is an ideal system, let’s see how it looks,

let’s draw this new system.

Replenishment buffers characteristically oscillate

between being nearly full and being somewhat empty. They oscillate between zone 3 and zone 2 –

rarely do they move into zone 1.

Movement into zone 1 is a signal for management action (action by

exception). If having 1/3rd of your

stock “sitting” in zone 1 sounds wasteful remember that this system is

frequency driven. Total finished goods

stock may well be 1/2 or 1/4 or even less of that previously required at this

first stage after manufacturing. Let’s

check that we understand why. In the earlier discussion on drum-buffer-rope

make-to-order we limited ourselves to the benefits that occur when excess

work-in-process is removed from the system, we “dried the system out” by at

least 50%; and lead time was reduced proportionally. We didn’t consider the “what if” when an

order consists of 1000 units of the same thing, surely we could manufacture

that as two lots of 500? In a way we

would have been getting ahead of ourselves, in fact the whole subject of

batching is so important that there is a further page on it called “batch

issues.” However, because batching is

endemic to make-to-stock we need to address it here to some extent. So let’s ask the what if. What if we have a batch of stock of 1000

units, and what if we made two smaller batches of 500 units instead? Well, each batch would move through the

process twice as fast as before. The

rationale is that most of the time that a batch spends on the floor is time

spent waiting, and therefore a batch of 500 waits half as long as a batch of

1000. Unconvinced about the

waiting? Go attach a balloon to a

batch or two and see what they are doing over a couple of days. So, if we dry the system out of excess

work-in-process and that reduces lead time by at least half, and then we

reduce batch size in-turn by half that will reduce lead time to a quarter –

without even trying. Of course we have

to run those batches twice as often, could that be a problem? Well not usually. It is not a problem as long as we don’t

turn a non-constraint into a constraint by too many set-ups. Now let’s look at two further considerations. Firstly; we don’t batch when we

replenish! Oops. Trying not to use the term “batch” from now

on is going to be so darn difficult, however, it is not politically correct

to talk about fixed-batches in replenishment

because they don’t exist, therefore we will talk about the variable replenishment aggregate size instead. As Schragenheim points out, in all of the

standard approaches to make-to-stock there is a buried assumption somewhere

as to a fixed batch size (8). We

assumed exactly that in our transitional approach above. So yes, common sense tells us that we must

aggregate some of the stock units some of the time, least we grind the system

to a halt, or we are Toyota, or we are very clever. However, we should strive to keep the size

of our replenishment aggregate as small as possible and variable; that

is, not invariably the same size each and every time. Secondly; we may have product

cycles. Sometimes when the

nature of the material is different for different stock we may wish to make

everything required with one material before we change to another. Or we might have a preferred sequence of

set-ups either up or down the size range or some other set of dependencies

that cause us to cycle through our manufacturing process. The good news is that cycle times will

decrease in proportion to our variable replenishment size reduction. Why is this so important? It is important because our

initial stock buffer size, and hence the physical inventory and financial

investment that we must carry, depends upon the resupply time. In the absence of product cycles and large variable

replenishment aggregates the manufacturing lead time determines the

resupply time. In the presence of product cycles, the time

for the completion of a cycle plus the manufacturing lead time

determines the resupply time. There is a more detailed explanation of the

characteristics of replenishment in the second part of the replenishment page

in the supply chain section. Be aware

that manufacturing professionals tend to misunderstand replenishment at first unless they have been

exposed to supply chain management. If

we have only ever been exposed to fixed batches of material then everything

tends to look like a fixed batch of material.

This is a very real and substantial block. Please check the replenishment page to test

your understanding. During the implementation phase of simplified

drum-buffer-rope in a make-to-replenish environment the removal of fixed

batch sizes and replacement with smaller more frequent variable

replenishment size orders is the critical parameter in determining system

behavior. If the demand in make-to-replenish is uncommitted,

then how do we plan? Well, the same

way as in make-to-order simplified drum-buffer-rope, we load replenishment

orders against our aggregate capacity – our daily or weekly capacity

multiplied by the material release rope length. The capacity is defined as that of the

weakest link in the process. We

shouldn’t fill more than about 80% of that capacity over any medium term

plan. Let’s add this to our model.

The amount of stock that we must hold in our stock

buffer depends upon the amount of time that it must “cover” for. The principle components of that time are

the reorder time and the resupply time.

We can define the stock buffer as follows; Finished Goods Stock Buffer = Average Demand x

(Average Re-order & Re-supply Time) Because we use averages for demand and for time we

use the margin of safety to accommodate that which we know least well, the

variation around the average values.

If the resulting buffer is too big it will soon become apparent and we

can, in fact we must, resize it.

Likewise, if the buffer proves to be too small then we will also have

to resize it. Re-order and resupply time are clearly the most

critical components. We have already

discussed the factors that lead to a reduction in resupply time, most of

which are within our own control; what then are the issues that determine the

re-order frequency? Policy of course! Whose policy? Our policy! Yep, there are not a whole lot of excuses why

re-order, which is totally under our own control in our own system, can not

be substantially reduced in duration.

If we are big enough to have a real problem then we will have a

computer and that can easily be interrogated more frequently. If we are small enough to have no problem

then we just need to do the sums more frequently. In drum-buffer-rope make-to-replenish, buffer

management once again provides us with both local control via buffer status

and global feedback in the form of buffer resizing via longer term trends in

buffer behavior. The model is the

same; the terminology is modified to suit the environment.

Stock buffer status is defined in the same way as a

time buffer; Stock Buffer Status = (Buffer Quantity –

Stock-On-Hand) / Buffer Quantity We have already used this concept with buffers for

work orders in make-to-order, exactly the same principles apply for stock

buffers in make-to-replenish. Let’s

illustrate the concept with a few diagrams for stock buffers. The following buffers contain varying

amounts of stock-on-hand (SOH).

Of the other buffers; C is in the green zone, zone

1, and of no concern, buffers A and D are within the yellow/orange zone, zone

2, and we should leave well alone unless we once again wish to tamper with

the system – and Deming taught us what happens when we allow that occur. So let’s not do it. By using buffer status we can prioritize different

product buffers amongst each other regardless of whether one replenishment

buffer covers a period of 2 months and 2000 units and another replenishment

buffer covers just 2 days and 20 units. In make-to-order the relative priority of released

work orders can only be affected by internal “things,” however, in

make-to-replenish the relative priority of stock orders can also be affected

by external changes in the market demand during the processing time. Because stock orders should be smaller and

more frequent it is also possible that more than one order for identical

stock can be in-process at the same time, this too must be taken into

consideration. Thus the stock order status for material on the

floor is (8); Stock Order Status = (Buffer Quantity –

Stock-On-Hand – WIP Ahead) / Buffer Quantity Let’s illustrate this with two different stock items

– “light blue” and “lavender.”

Buffer status tells us about the end condition of

the system and whether to check or maybe facilitate work already released for

production. However, without customer

due dates as in make-to-order jobs, how can we prioritize new jobs for

material release? To do this we must

replenish the buffer to its full capacity allowing for current stock-on-hand

and current work-in-process, thus; Stock Release Priority = (Buffer Quantity –

Stock-On-Hand – Total WIP) / Buffer Quantity For the example that we just used with “lavender”

and “light blue” finished goods stock buffers, we have the following release

priorities.

The actual amount of material released to replenish

the buffer will be the amount required to bring it be back to the full buffer

quantity; Stock Replenishment Quantity = Buffer Quantity –

Stock-On-Hand – Work-In-Process When demand is generally high, then the time between

one stock order being released and the next order for the same stock will

increase because each order is now larger and takes longer to process,

however overall system set-up will decrease as a consequence. Conversely, when demand is light, the time

between each order will decrease because each order is now smaller and takes

shorter time to process. Overall

system set-up will increase as a consequence.

Schragenheim argues persuasively how this mechanism self-adjusts to load

and can be used to drive system stability (8). Do you notice something important? We have moved away from fixed batch sizes and away from the fixed schedules of transitional

make-to-stock. The re-order frequency

and resupply frequency and quantity are now totally determined by the

characteristics of the system that we implement and the demand

characteristics of the customers. This

is make-to-replenish. In fact we are not entirely free of fixed

schedules. In replenishment we have at

the very least; rechecking, re-ordering and resupply. The re-ordering and resupply are indeed

free from fixed-frequency scheduling but there is one last hold-out – the

rechecking. Most likely we will still

batch this in time – to once a day, towards the end of the day maybe when we

“know” what we have sold that day. There is an alternative stock buffer sizing rule for

finished goods stock buffers.

Schragenheim and Dettmer use the term “emergency level” to define zone

1; they suggest that zone 1, the red zone or emergency level, should contain

sufficient stock to cover the time required to expedite a medium size

replenishment order through the system (14).

Three times this value will therefore define the full buffer size. Let’s make sure that we understand all of the terms

that apply to a stock buffer, let’s use the light blue buffer as an example.

A make-to-order system has just one, or maybe two,

buffers – either the shipping buffer or a constraint buffer and a shipping

buffer. In essence the system must

always have a drum buffer.

Make-to-stock therefore seems overwhelming because every stock buffer

becomes a drum. Thus we have move from

just one or two buffers to maybe many hundreds or even thousands of

buffers. Nevertheless we need to

address both the aggregate behavior of the buffers and their individual

behaviors. A buffer hole occurs whenever there is an incursion

into zone 1, the red zone, of the buffer.

Let’s draw this for a stock buffer.

Unlike make-to-order where each job is discrete and

a buffer hole can be quantified when the job is finally completed,

make-to-stock is continuous – we continuously replenish and customers

continuously deplete our replenishment.

So we can not put a mark in the ground that says “hole closed on this

day.” Instead we must continuously

monitor the number of units missing and the number of days that they are

missing from zone 1. This is the

measure that will tell us what is happening in individual buffers. We must record the number of units “missing” from

zone 1 each day that any units are missing and we must aggregate this over

our reporting period – be that a day, a week, or a month. The measure is unit-days late. From the buffer hole data we can construct a more

meaningful measure. One that includes

the value of the problem. In a

for-profit environment these are known as throughput-dollar-days (late) and

inventory-dollar-days (wait). Let’s

add these to our diagram.

Throughput-dollar-days late is our unit-days of material

missing from zone 1 of the buffer multiplied by the expected throughput of

the product. This way both the size of

the hole and the value placed in jeopardy are taken into account. We must remember that the purpose of a

buffer hole is an internal warning to us that we may “ping” a customer. Throughput-dollar-days tells us how loud

that ping could be – of course we will absolutely strive to remedy the

problem before it reaches the customer. Inventory-dollar-days has an important role in

make-to-replenish. No-longer does it

just protect us from gaming the system – having no zone 1 penetrations by

loading excess work-in-process; it now alerts us to the ageing of stock. What if the risk of “pinging” a customer becomes

more frequent and greater? Surely this

must be a message that we need to increase the size of the particular buffer

concerned – unless of course we want to spend all our time and energy

fire-fighting (and we put our fire-fighting gear away – right?). So buffer penetrations that are too

frequent into zone 1, the red zone, require an increased in buffer size. Conversely, buffers that are always in zone 3, the

green zone, indicate a need for reducing the size of the buffer. We monitor the behavior of our protection and if it

is insufficient, or if it is over-protective, we make adjustments to the

system to accommodate this. In the earlier re-order system we were able to mix

make-to-order and make-to-stock by giving make-to-stock orders a due

date. In mixed

make-to-order/make-to-replenish we can do away with the due date for

stock. Essentially we have two

drums. We have two drums because we

have two markets; those that can’t wait (make-to-replenish) and those that

can or must wait (make-to-order). The

typical situation here might be standard items (make-to-replenish) and

special one-off items (make-to-order) – even though we might make several

hundred or several thousand units in one male-to-order. Of course the aggregate load of the two

drums can’t exceed the availably capacity of the most capacity constrained

internal resource. But then simplified

drum-buffer-rope allows us to load against that aggregate capacity. How does this look, let’s see.

We would hate to sacrifice a late make-to-order job

because we thought the demand for a make-to-replenish order was more urgent,

only to then find out that the make-to-replenish wasn’t urgent at all – the

demand had dropped away again. How can we

manage such a duality? We are dealing

with both time (make-to-order) and with quantity (make-to-replenish). Well, Schragenheim shows us how; with the

buffers of course. Let’s have a look.

This is the power of Schragenheim’s buffer status

methodology. “Even though the

calculation of the buffer status is different, they are fully comparable

(8).” It seems almost quaint now, but in 1986 when

Goldratt and Fox wrote The Race, the

role of reduced inventory was still, in many peoples’ minds, an open

question. Never-the-less, they

proposed six competitive edge issues built around; product, price, and

responsiveness, in which reduced inventory has a positive effect and set out

to demonstrate their case (15). These

issues are listed below.

Their demonstration of the case is the reason for

accepting in the measurements section that inventory reduction does in fact

have a positive impact via future throughput on the bottom line measure of

net profit. Of course time also

appears to have substantiated the importance of inventory reduction in all

six cases. The objective of Theory of Constraints and

drum-buffer-rope however is not to reduce inventory per se,

it is to increase throughput – the rate at which the system produces money or

goods or services in order to move the system towards its goal. Most often inventory reduction is a

desirable and feasible outcome; but it supports the objective of increased

throughput, it is not an objective itself. Making Throughput the objective in Theory of Constraints

is quite different from other approaches.

In the pursuit of bottom line improvements traditional cost management

focuses primarily on reducing operating expense, and is neutral about

inventory. Just-in-time focuses

primarily on reducing inventory, and is neutral about operating expense. Constraint management focuses primarily on

increasing throughput and is neutral about operating expense. We can illustrate this as follows;

All three approaches; traditional management,

just-in-time, and constraints management are naturally interested in

increasing throughput, but only constraint management has this as its primary

focus. Let’s run past this in a different direction. Just-in-time, and to some extent kaizen,

are noted for actively lowering inventory in search of problems. The exposed problems are then resolved and

throughput may go up as a consequence.

Theory of Constraints is almost the reverse. It is noted for actively seeking out

problems to increasing throughput. The

problems are resolved and inventory may go down as a consequence. Problem solving via inventory reduction is well and

good for work-in-process, but what about raw material and inwards good

then? Reducing raw material inventory

only to find the problem is with a vendor is not especially useful unless the

vendor is willing to improve. Don’t

let just-in-time zealousness erode protective raw material supply. Just-in-time works in Japan because the

obligations of mutual interdependence are much greater. In Western businesses, if there is a

particularly unreliable vendor then, at the very least, we must protect

ourselves with as frequent as possible small-lot replenishment. Let’s explore this further. Many businesses, especially make-to-stock, have

standard common raw material or inwards goods items that are keep as

stock-on-hand. Essentially theses are

raw material stock buffers. In the

introduction to raw material and finished goods buffers we remarked that raw

material is a more exacting environment than finished goods. Why is this? Well, ask any purchasing officer or

in-wards goods officer who failed to have the right material in the right

place at the right time for production.

In reality we have almost no control or authority over the external

re-supply chain and yet we are expected to assume full responsibility for

managing the goods within it. How do

we best protect our system in this case? Let’s draw our simple raw material stock buffer

feeding our production system and work outwards from there.

Inwards Goods Stock Buffer = Maximum Demand x

(Average Re-Order & Re-Supply Time) The key point is that we must accommodate the

maximum anticipated demand and the maximum unreliability of the vendor. We are really applying Goldratt’s first two

rules of business; (1) “be paranoid,” and (2) “be paranoid.” The 3rd rule is also useful – “don’t get

hysterical.” We guard against hysteria

by frequent re-orders. Why? Let’s see. The replenishment time is composed of up to 4 components; (1) Our re-order frequency – and hence

duration (2) Vendor cycle frequency – and hence

duration if it is not ex-stock (3) Vendor process lead time – and

hence duration if it is not ex-stock (4) Vendor order processing &